Managing risk and optimizing returns are common goals shared by all developers. Flat, soft land can often come with a high price tag leaving developers to construct PV on rocky, hilly terrain to take advantage of the higher margins these discounted parcels offer. But while these opportunities may look lucrative at the start, construction issues can easily turn a good project bad.

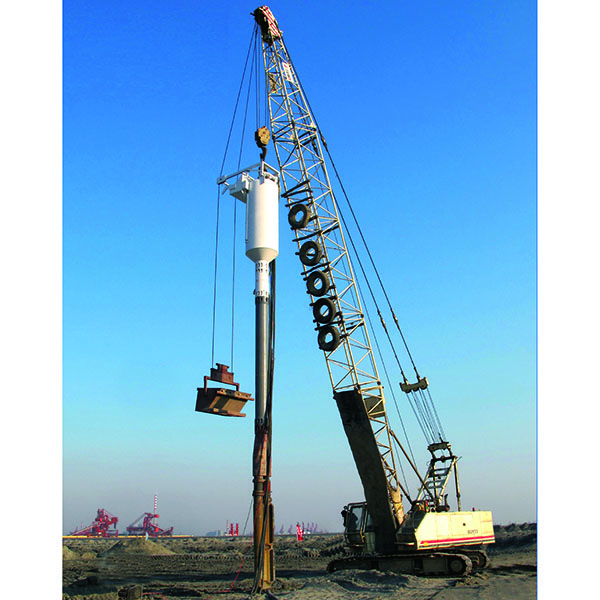

Selecting the right ground-mount foundation is key to optimizing a project’s cost and risk profile. Success lies in knowing how to weigh the costs and benefits properly to pencil out strong projects with the best returns. Vibratory Pile Driver Control Valve

There are costs and advantages to both pile foundations and ground screws.

Ground screws present higher up-front material and construction costs — and some manufacturers such as Terrasmart even offer to eliminate 100% of the refusal risks, minimize land grading, and slash other civil expenses. Paired with adaptable racking, ground screws can deliver reliable returns from unreliable sites.

On the flip side, pile foundations are the standard option for cost-effective PV. They can be deployed quickly and reliably — on typical sites. They are not, however, the most effective option for rugged or sloped terrain or unpredictable conditions that can present costly and schedule-derailing refusals.Risk management

Refusal risk plays a large role in deciding what foundation is optimal. Refusal occurs when a pile does not advance 12 inches over 30 seconds or takes more than 5 minutes to install. This results in the pile not being able to be installed to the specified embedment depth. Dense soil conditions, cobbles, and boulders can cause refusal. When refusal occurs it requires additional time, resources, and materials to mitigate; often sending projects over budget and delaying project schedules. It is important to note that ground screw eliminate refusal risk.

Every project comes with a unique set of drivers—end-of-year projects driven by compressed deadlines or projects with more time flexibility but face tighter budget constraints. The amount of risk developers can absorb requires a case-by-case assessment. Selecting a partner with an objective, consultative approach to foundation options can make all the difference.

With decades of experience, our lead engineers put together a cost/benefit analysis comparing driven pile and ground screw foundations.

We started with comparing two 10-MW sites with different subterranean profiles: one with soft soil and the other posing high refusal risks. For both sites, we compared component material costs, installation costs, and time using either piles or ground screws.

At first glance, ground screw prices are higher than piles— screws cost 26% more. But in terms of installation time, screws are faster to deploy: 40% more ground screws can be installed in a day than piles.

However, when examining different ways to remediate refusals — which ground screws do not require — it’s clear that piles can quickly erode budgets and schedules. Using a standard drill-and-drive method, remediation cost for a pile adds an additional $250 per foundation to the initial $68 per unit install price. They also require more time at the rate of 50 units per day. Scenarios that allow for a “cut and drill” remediation add $75 per pile and 100 foundations per day to the schedule.Comparing options in a high-refusal environment

Refusals on a project can swing both ways. However, defining a standard approach to each site using a scenario with a 50% risk of refusal allows for a cost and schedule comparison between piles and ground screws.

For a soft 10-MW site, piles cost $7,200 less than screws, can be installed for $220,000 less, and go in four days faster than screws.

But on a 10-MW project with a 50% refusal rate, piles are no longer an effective option. While ground screw costs and time requirements remain constant, piles cost $19,500 more in materials, $57,500 more to install, and require a 24-day extension to the construction schedule. Read the full analysis here.Breakeven Analysis

Admittedly, a 50% refusal site is not the norm. So then, at what refusal percentage do ground screws outperform piles? What are the implications on cost and project schedule? What is the break-even point for both cost and installation time to determine an acceptable refusal rate?

Installation costs alone indicate that a 29% refusal rate makes a site a good candidate for ground screws. Above this break-even point, installation cost for piles would exceed the $400,000 needed to install a ground screw system.

Refusals also impact schedules. In this scenario, both pile and ground screw systems would require a 26-day schedule, allowing for a refusal rate of up to 7%. Beyond that break-even point, each additional 15% of pile refusals would add another day to the schedule.

While a 20% refusal rate is the breakeven point in this scenario, we understand that every site is different, and each customer has their own set of goals and priorities. Although there is no one-size-fits-all, sites with 20%-30% refusal rate require geotesting and engineering expertise to ensure you have the best solution for your project.No matter the site, Terrasmart delivers the right foundation

As a true partner for success, Terrasmart is the only provider on the market to offer both ground-screw and driven-pile foundations. Through careful objective analysis of each site’s underground profile, we can deploy our deep experience across various types of foundations. Leverage our efficient solutions to optimize projects across all site conditions. We’re in this alongside EPCs to maximize ROI, minimize risks and costs, and determine the best path to project success.

Learn more here.Listen to more in-depth conversations on Solar Builder's YouTube channel Our most popular series include: Power Forward! | A collaboration with BayWa r.e. to discuss higher level industry topics. The Buzz | Where we give our 2 cents per kWh on the residential solar market. The Pitch | Discussions with solar manufacturers about their new technology and ideas. Tags: Terrasmart

Our most popular series include: Power Forward! | A collaboration with BayWa r.e. to discuss higher level industry topics. The Buzz | Where we give our 2 cents per kWh on the residential solar market. The Pitch | Discussions with solar manufacturers about their new technology and ideas.

Other Benjamin Media, Inc Brands: Compact Equipment | Trenchless Technology | Tunnel Business Magazine | Utility Contractor | Water Finance & Management

Hydraulic Mine Drilling Machine ©2023 Copyright Solar Builder Magazine | Wordpress Website by OuterBox